HOME > Products > TPCD Series PCD

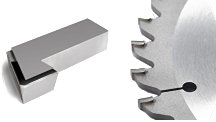

TPCD Series PCD

Trustwell’s PCD is produced by sintering selected diamond particles at high temperature and high pressure. It has high strength and excellent wear resistance. It is mainly suitable for cutting tools and wear-resistant tools for non-ferrous metals and metal-based composites.

Product name・Size

Cut parts are also available.

| Product name | Grain size μm | Φ mm | Diamond layer thickness mm |

Overall thickness mm |

|

|---|---|---|---|---|---|

| FB 685 | Ultra fine grain | 1 | 63 | 0.5 ±0.1 | 1.6 / 2.0 / 3.2 |

| FB 511W | Medium grain | 10 | 63 | 0.5 ±0.1 | 1.6 / 2.0 / 3.2 |

| DM850 | Ultra fine grain | 0.75 | 46 / 52 | 0.5 ±0.1 | 1.6 / 2.0 / 3.2 |

| DM002 | 2 | 48 / 55 | 0.5 ±0.1 | 1.6 / 2.0 / 3.2 | |

| DM005 | Fine grain | 5 | 48 / 55 | 0.5 ±0.1 | 1.6 / 2.0 / 3.2 |

| DM010 | Medium grain | 10 | 48 / 55 | 0.5 ±0.1 | 1.6 / 2.0 / 3.2 |

| DM025 | Coarse grain | 25 | 48 / 55 | 0.5 ±0.1 | 1.6 / 2.0 / 3.2 |

| DM302 | Mixed grain | 2~30 | 48 / 55 | 0.5 ±0.1 | 1.6 / 2.0 / 3.2 |

Features

| Product name | Features / Use |

|---|---|

| FB 685 |

|

| FB 511W |

|

| DM850 |

|

| DM002 |

|

| DM005 |

|

| DM010 |

|

| DM025 |

|

| DM302 |

|